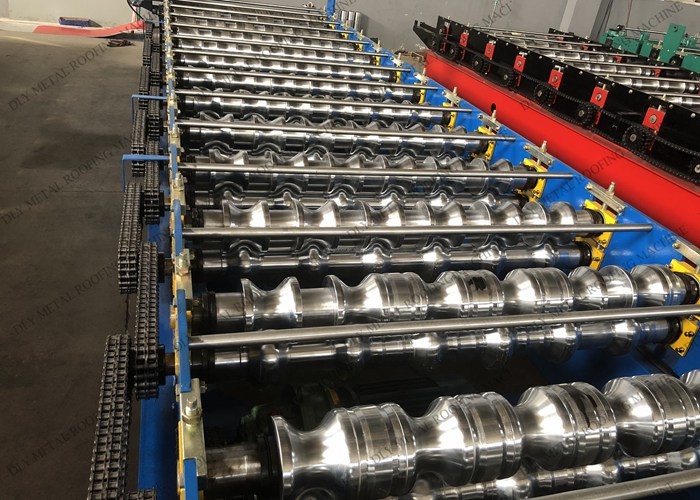

DLY Metal Roofing Machine is a professional supplier of different model of metal

roofing machines, including Tile Roofing Machine, Trapezoidal

roofing machine, CUZ Purlining Forming machine, light steel house

machine, and related accessory parts.

Since the company's beginning in 2012, our constant orientation is

"quality first, credit first", We keep growing step by step and

work hard to be a reliable partner with high quality products and

professional service.

Many years of experience enable us to face all the challenges, and

listen to every customers’ need. Think what you think and do what

you need. You do not need to worry about quality, price, delivery

time, shipping, guarantee, after-sale service and etc., you have

all when you have us,we are your reliable partner.

Our products have been exported to Slovenia, Bosnia and

Herzegovina, Serbia, Uruguay, Russia, Canada, Australia, Nigeria,

Zambia, Tanzania and etc. We were proud to receive recognized by

our valued clients!

About Our products

We have professional design team, advanced equipment, strict

production process and quality control system to ensure every

product is qualified before shipment, all of the problems are

solved in production, never leave trouble to clients.

Technological innovation is crucial to the company's survival and

development. We always pay great attention to the continuous update

of products to meet the needs of different customers and market

demands.

About Our service

Pre-sale service is the first step for us to establish trust

-provide relative product information

-answer customers' questions and give technical suggestions

-provide free quotation list according to customers’ request

-supply samples for test

-welcome customers visit us at any time

In-sale service is the key step during production, it is guarantee

for quality and integrity.

-confirm every detail request with customer before start production

-report production process to customer

-Repeated machine test to ensure stable use

-free service for booking container and container load

After-sale service is not only very important for customer but also

for us, customers’ feedback encourage us to continuously improve.

-provide technique guidance related to use product

-supply one-year warranty period for the machine

-provide whole life technique assistance

-provide 24h*7days service